Isolation of critical signals just got easier…

- Test switching regulator circuitry for internal nodal isolation

- Crystal frequency measurement to remove the “input” side

- Test RF circuitry with power off

Circuit Check’s bi-level and multi-stage fixtures combine multiple test levels in a single fixture using controlled actuation and selected probe travels for powered and unpowered tests.

Isolation of critical signals just got easier…

Dual Stage fixturing is taken to the next level; now both long and short stroke probes can easily contact the top and bottom of your UUT. Your test program controls pneumatic “pencil” cylinders that switch between either all long stroke or all probes contacting the UUT. A robust 0.050″ delta is maintained between the two different stroke probes.

This unique design keeps the UUT under vacuum in both stages not exposing it to sudden strain events between stages.

The typical test cycle:

This cycle can easily be reversed and the sub-set of probes contacts the UUT first. The combination of long and short stroke probes is only limited by the tester’s resources. The upper “Quick Plate” maintains a balanced support of the UUT during dual stage testing and provides probe guiding for top side test pads as small as 0.018″. The lower “Quick Plate” guides probes repeatedly to contact 0.016″ test pads. U.S. Patent 8,754,665

Pneumatic Multi-Level

Multi-Level fully pneumatic fixtures provide the broadest array of in-circuit testing options, allowing powered, non-powered and functional tests to be performed. Often, active component cooling is required during functional testing and Vortex cooling is suited for this style fixture. Additional testing can be achieved with insertion of interposer cards into connectors. Conventional probe spacing is 100 – 39mil and socket-less spacing is 75 – 31mil.

Vacuum Dual Stage “Dual Check 2.0”

Dual Stage fixturing designed specifically for dual sided, dual stage powered and non-powered testing. Vacuum actuated with pneumatically controlled leveling. This unique design keeps the UUT under vacuum in both stages not exposing it to sudden strain events between the test stages. Conventional probe spacing is 100 – 39mil and socket-less spacing is 75 – 31mil

Vacuum Dual Stage “Dual Check”

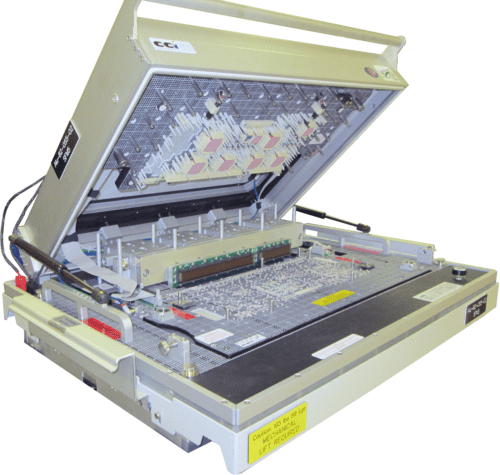

Our original vacuum dual stage fixture is for traditional in-circuit and functional testing on both surfaces of the UUT. The design uses the tester’s two vacuum ports to independently control the fixture’s two stages and can accommodate up to 400 long stroke probes and 3000 short stroke probes. Conventional probe spacing is 100 – 39mil and socket-less spacing is 75 – 31mil.

Actuation Methods

Vortex Series

Wireless

Tight Proximity Probing Technology

Drop-In

Multi-Stage

Topside Probing

Test Fixture Adapters

High Node Count

In-Line / Board Handler

FEA and Strain Gauge Testing

Expanding In-Circuit Capabilities